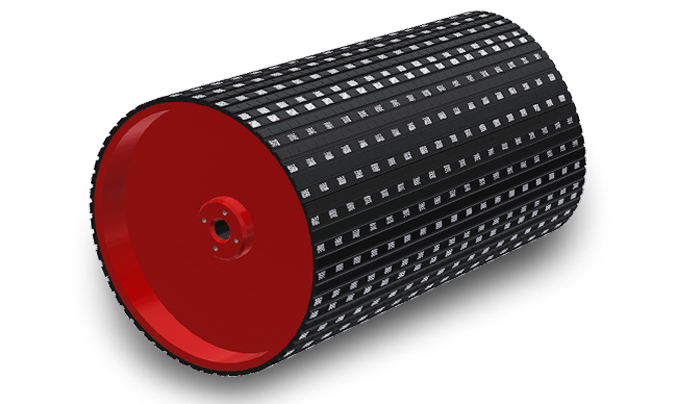

Beltram Full Ceramic Pulley Lagging

When conventional rubber lagging fails to correct belt slippage, the solution is BELTRAM Full Ceramic Lagging — featuring the highest coefficient of friction available.

FEATURES AND BENEFITS:

- Best in class 80% ceramic tile coverage

- Two to three times the friction of conventional rubber lagging

- Rubber-backed ceramic tiles with a raised “buttons” that embed them

- selves into the belt’s underside for non-abrasive traction

- Exceptional performance in wet, muddy, or dry conditions

- None of the sharp particles or abrasive edges associated with other ceramic lagging products

- Fast, easy installation that doesn’t require removing the pulley from the conveyor

Applications:

- Any operation experiencing slippage problems

- For systems with pulley diameters from 12” — 72” (300— 1800 mm)

Specifications:

- Temperature rating: 5° F to 185° F (-15° C to 85° C)

- Rubber compound: SBR

- Rubber hardness: 68 + 3 Shore A

- Thickness: 12 mm

- Ceramic compound: Aluminum Oxide (Al2O3)

- Ceramic hardness: 83 HRA Rockwell Hardness Scale A

- FRAS (Fire Resistant Anti-Static) MSHA Certification# MHSA No. IC-190